Bentley’s $198,725 Flying Spur sedan is more sustainable due to ESI Group’s virtual prototyping process

Engineers test each component in digital form to reduce the car’s overall weight and cabin noise before building any physical parts.

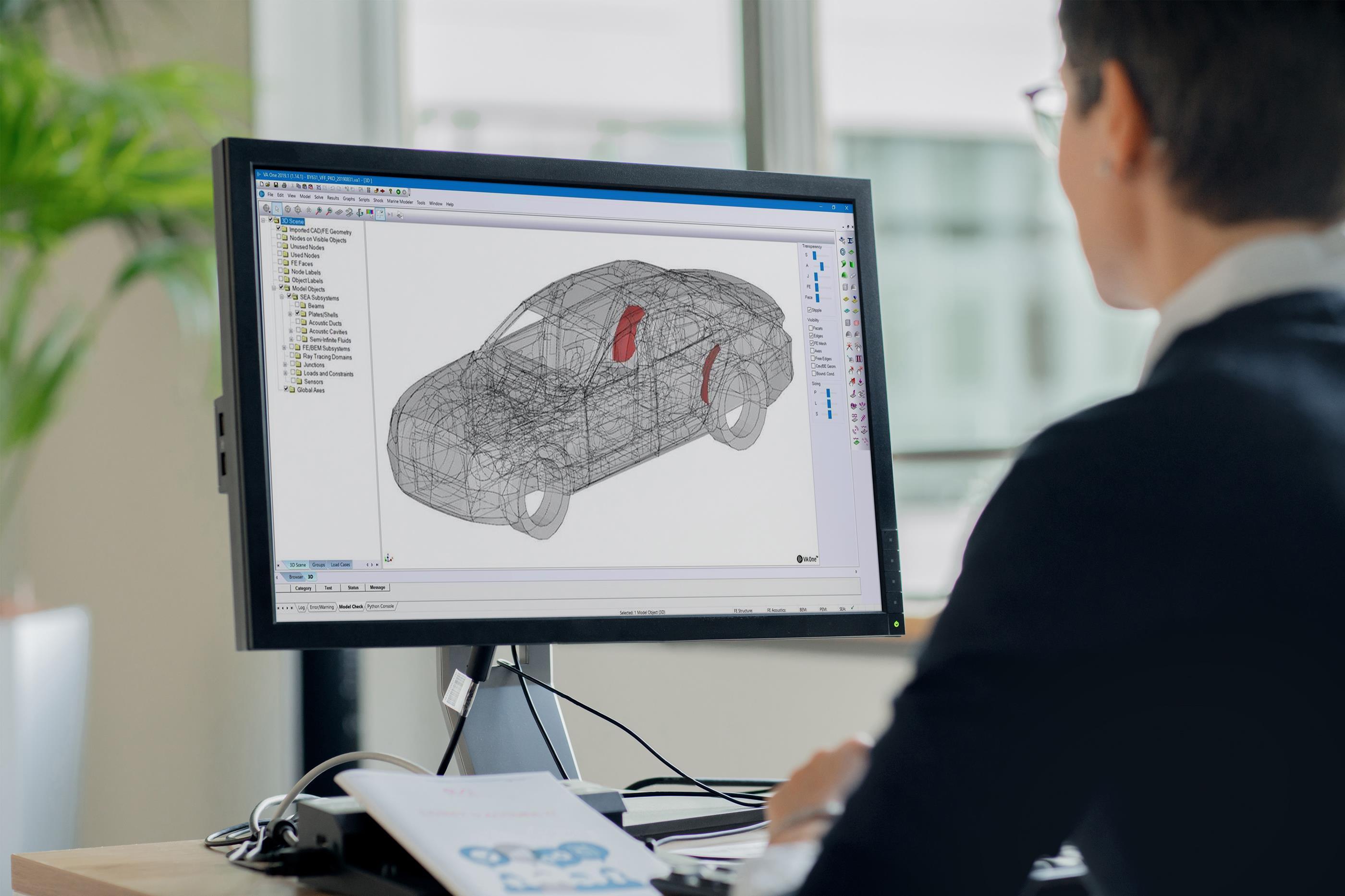

Bentley worked with ESI Group to use a virtual prototyping process to reduce cabin noise and the overall weight of the 2021 Flying Spur V8.

Image: Bentley

Luxury car maker Bentley is using virtual prototyping to create a quieter ride in the Flying Spur and make the entire process greener. The carmaker is working with ESI Group to take the design work digital.

Simon Noble, acoustic engineer at Bentley Motors, said in a press release that virtual prototyping helped the company optimize each component of the car virtually before building the physical parts.

“Virtual prototyping means fewer prototypes have to be built, and we reduce our testing mileage,” he said. “It also helps influence the design and engineering of the car at an early stage and affords significant benefits in the extensive testing phase.”

The 2021 Flying Spur is $198,725, according to Car and Driver. The 2021 Flying Spur V8 is 100kg lighter than the Flying Spur 2021 W12, according to the company.

SEE: English company modernizes Phantoms, Bentleys and Jaguars with electric engines (TechRepublic)

The ESI Group used virtual prototyping to create digital mock-ups that helped identify noise, vibration and harshness before building a physical version of the car.

“The virtual prototyping helped to reduce physical parts in the test phase and save time,” Jonas Fredriksson, managing director ESI Northern Europe, said in a press release.

With the traditional prototyping process, each design decision has to be validated with a physical product to study the behavior of each part toward each other and its impact on the final product, according to a spokesperson from ESI.

“This takes time and has a cost in raw material,” Fredriksson said.

Using a virtual design process, everything is done in a digital mockup with a virtual representation of each part and the car as a whole.

“Every choice of material and component positioning is no longer physically prototyped to be tested, but instead every test is run virtually as a simulation,” Fredriksson said. “This solution offers much more freedom: the number of physical prototypes is reduced while increasing the number of tests that can be done.”

By performing realistic virtual simulation of sound and material behavior of the design, Bentley eliminates the need to make physical prototypes. The virtual process allows designers to validate and test virtually, get it right from the beginning and avoid costly changes, waste of prototypes and time.

“The digital design process makes the design of the car more economical in terms of time and cost and especially raw material,” Fredriksson said.

Bentley described the process this way in a press release:

“This zero-waste, highly innovative process is also in line with Bentley’s ground-breaking Beyond100 strategy, targeting sustainable global mobility leadership. The company’s ambitious aim is to be end-to-end carbon neutral by 2030, with the Crewe operations climate positive thereafter.”

The ESI spokesperson said that the virtual process makes it easier to test materials while also consuming less and polluting less.

A Bentley spokesperson said that engineers conducted weight optimization processes for 40 components on the Flying Spur to keep the vehicle’s weight as low as possible.

ESI also works with Renault to do virtual prototyping. The spokesperson said that Renault got the highest rating on Europe’s safety test certification for the Clio 5 with a single physical prototype. Other Renault models needed anywhere from 10 to 28 additional prototypes to pass the certification process.

The ESI group has 50 years of experience with virtual prototyping and has worked with car companies, including Safran, Audi, Latecoere, Kion Group, Volkswagen and Honda, as well as defense and naval companies.

Also see

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.